Custom processing is the brand Changzhou Premking model GLA1000-16

Power of 1 (kw) dimension 2000*710*2200 filling head number 16

The filling volume of 1000 (ML) 80-230 (mm) for bottle bottle diameter 33-100 (mm)

Production capacity (120 cans per minute) filling accuracy + 1 (%) type of packing bottle First, an overview

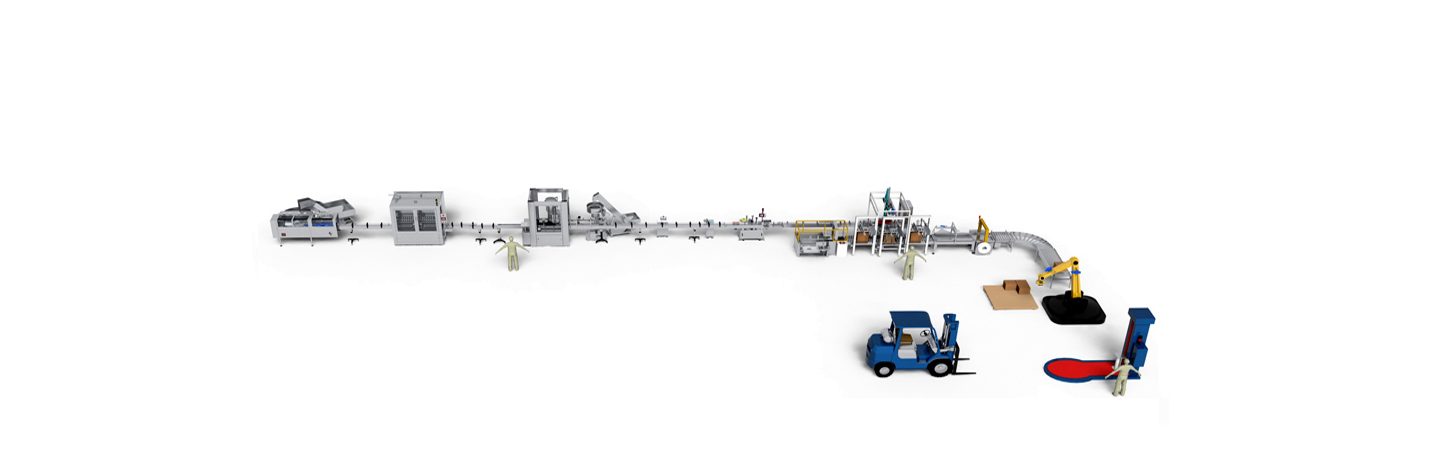

GSA5000-6 intelligent high viscosity filling machine is suitable for the packaging of pesticide, emulsion, suspending agent and high viscosity material. The whole machine is a straight line structure, which is driven by the servo motor and the principle of volumetric measuring and filling, which can realize the high precision of filling dose. Using PLC control, touch type man-machine interface, the whole operation is convenient and intuitive.

Two, equipment characteristics

1 using PLC programming control, servo motor drive stability of the double screw drive mechanism, to ensure the high accuracy of piston movement, to achieve a precise filling. Filling machine does not fill the bottle, the bottle automatically suspended from the bottle when the bottle, and after the road equipment to achieve linkage function.

2 replace the filling specifications, can be a key to complete the dose adjustment in the touch screen

3. The cylinder drives the filling head running submersible filling way, with the set of variable speed filling function, reduce foaming material in the filling foam to prevent overflowing of the materials caused by the pollution of a bottle mouth.

4. In the lower part of the filling head is installed there is independent of the cylinder to control the residual liquid collecting groove and ensure the filling head after the closure of the liquid does not leak to the outside of the bottle.

5. Optimization of import and bottle of program control, can choose normal / fast modes, just on the touch screen to open the function; fast in and out of the bottle when the bottle and the bottle, bottle action without delay, improve the production efficiency of 25%.

6. The latest PTFE carburizing technology of piston seals, improve the piston seal antiwear properties and applicability of the material, effectively solve the piston type filling machine of EC, water soluble suspension agent, high viscosity material can not be universal.

7 this machine using high-quality SUS304 stainless steel, good antiseptic effect. Outsourcing of stainless steel and tempered glass door cover the body sealing, the filling head above reservation outlet (nozzle aperture diameter 100) with factory lead wind system connected to discharge the waste gas generated in the process of the filling.

8 operating interface to protect the processing, so that the use of the machine more safe, rest assured.

9 filling machine does not fill the bottle, the bottle is not free from the bottle when the bottle is not free, and the rear side of the machine is equipped with the coordination of photoelectric, and after the road equipment to achieve linkage function. |