Custom processing is type filling sealing machine brand Changzhou Premking

Type XC10-6 4.5 power (Kw) weight 1000 (kg)

3500*1360*2100 (mm) packaging materials, plastic packaging type bottle

Production capacity of 100 (Ci /fen) automatic degree of automatic application of fruit juice drinks, oral liquid, liquid alcohol, milk tea, skin care First, an overview

This machine is set into the bottle, sealing, cover, screw cap, bottle and one catch cover positioning screw, machine for rotary structure. In the process of the rotary cover without injury bottles, no injury cover phenomenon, high efficiency, high pass rate, smooth operation, the use of a wide range, and can be comparable to similar foreign products. The machine is suitable for various kinds of regular glass or plastic bottles with various kinds of outer cover, and the cover is used to grab and cover the cover, and the rotation of the outer cover is completed in the bottle turning process. The whole machine adopts PLC control, touch type man-machine interface, convenient and intuitive operation.

Two, equipment characteristics

1 rotary structure, using special grasping grasping cover cover device, stable and reliable. The inner side of the cover is designed with wear resistant rubber, which can effectively prevent the injury caused by the rotating cover.

2 screw the bottle and add into the bottle detection device, to achieve no bottle cap, bottle, bottle inverted automatic shutdown alarm. 2 screw the bottle and add into the bottle detection device, to achieve no bottle cap, bottle, bottle inverted automatic shutdown alarm.

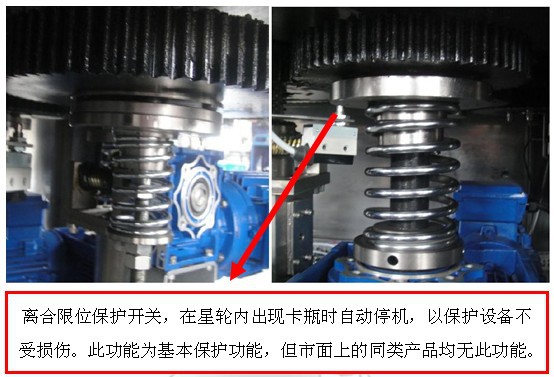

3. All the driving section are equipped with clutch mechanism, the import and the bottle star wheel appear card bottle or spindle torque overload automatically from the merger shutdown alarm. 3. All the driving section are equipped with clutch mechanism, the import and the bottle star wheel appear card bottle or spindle torque overload automatically from the merger shutdown alarm.

4 the use of patented technology to ensure the stability and reliability of equipment.

5 check design of rotary knife, belt clamp, end of rotary bottle pad, suitable for all kinds of glass or plastic bottle cap when the rotation stop in.

6 out of the bottle side of the double conveyor belt structure and the installation of intelligent detection device, the normal delivery of qualified bottles, unqualified (no cover, crooked cover, no aluminum film cover) bottle, the use of swing cylinders, automatically diverted to another conveyor belt. When the rotary cover machine is automatically suspended after the bottle is blocked, the device automatically runs after the recovery of the bottle blocking situation.

7 on the conveyor belt is equipped with anti - cover, non - aluminum film cover automatic elimination device; to ensure that all the cover is qualified. At the same time with photoelectric detection in transmission belt cover, automatic stop arrangement with the cover, no cover, automatic alarm.

8 the machine for the electric lift regulation, the replacement of the specifications only need to operate in the touch screen to achieve a high degree of adjustment. Quick change module import and starwheel bottle design, and engraved with the symbol of the diameter of the different types of bottles, at a glance, replace the specifications of the bottle type faster and more convenient.

9 reverse cover automatic drop. Ensure no reverse cover into the machine, the lower cover rail adopts integral nodeless track, thereby effectively solve the problem.

|